Installation and Setup

Installation - Each User. Installation - Multi-user. Language Translations. Personalize Your Templates.Systems2win Training.

Quick Start Initial Training. New User Training. Training Matrix. Systems2win Leadership. Training Classes.Lean Training

Lean Training and Coaching. Lean Principles. Muda 8 Wastes. Goal - Lean Flow. Roadmap - Lean Journey. Value Stream Mapping. Standard Work. Hansei Lean Thinking. Lean Dictionary. Online Lean Training. Lean Leadership.Microsoft Office Training

Excel Training. Excel Drawings (without Visio). Excel Charts. Word Training. PDF Training. Document Storage and Naming.Support

Support.Value Stream Analysis

Excel templates and charts, with online training and videos

to Measure, Analyze, Improve, and Control your Value Stream

The biggest strength of your Systems2win Value Stream Mapping template is Value Stream Analysis

If your organization has not already provided a license, download your free trial now

Before you begin

Value Stream Analysis

The training on this page assumes that you have already:

- Organized your leadership for your lean transformation and trained your value stream team

- Followed the instructions for how to do value stream mapping to observe the 'As Is' state of your process

- Entered your units of measure and data into your value stream mapping template

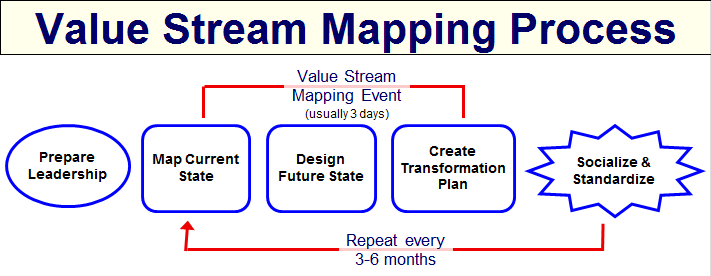

Road map for a typical

Lean Transformation

Value Stream Analysis Training

Contents

The Eye Catchers

The Layers

- Simultaneous Processes

- Critical Path

- Pre and Post-Production

- Drill-downs to and Roll-ups from Related Documents

Leadership

- Lean Journey - Status

- Lean Management Systems

Demand and Capacity

- Different units of measure for different processes

- Capacity must be greater than Demand

- Cycle Time must be lower than Takt Time

- Smallest Possible Staff

- Value Stream Capacity

Measures Within and Between Processes

- Lead Time — When can we have it?

- Distance

- Steps

- Cost

Critical Path — Deep Dive Analysis

- Productivity — considering ALL the factors that affect Capacity and Cycle Time

- % Complete and Accurate (Rework)

- Cumulative Scrap

- Guaranteed Turnaround Time

- Optimum Batch Size

- Path Codes and Scenarios

User-Defined Fields and Metrics

- Using all the power of familiar Excel — to make your value stream map yours

Search

Use CTRL+F

to find keywords

within this page

More VSM training

See the Section Menu

with links to more pages

with more training for

value stream mapping

Pop-up Help

In any Systems2win template,

click any row or column header for pop-up help

Value Stream Analysis

The Eye Catchers

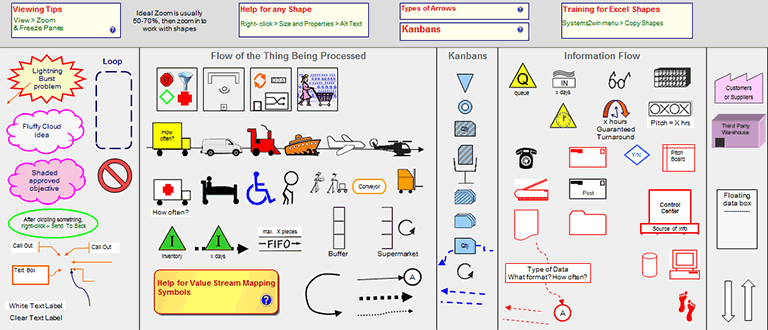

Value Stream Mapping Symbols

What catches most people's attention when they first view a value stream map are the value stream mapping symbols, which have been called "the language of Lean", and are so important that we have devoted an entire training page to them.

Charts

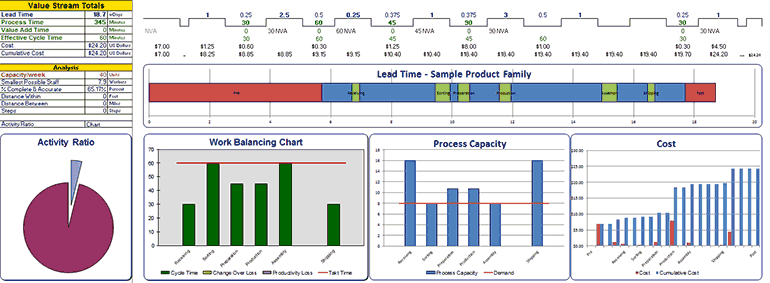

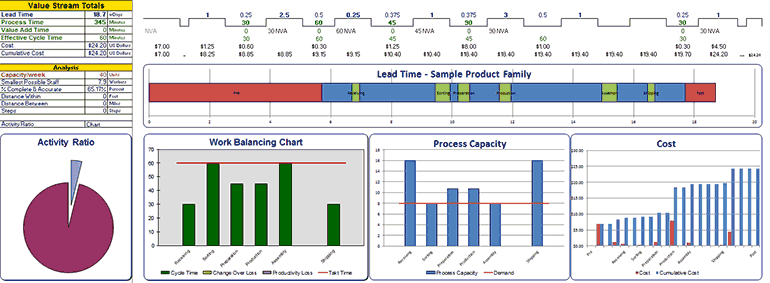

The next thing to catch attention are the Charts.

Your Systems2win Value Stream Mapping template comes with 5 pre-defined charts.

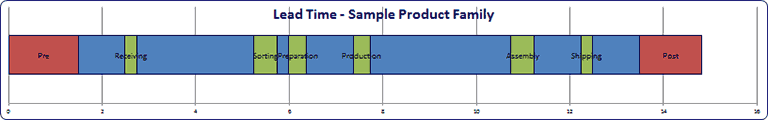

Lead Time Chart

Process Lead Time within your Critical Path processes are in green.

Queue time between your Critical Path processes are in blue.

If you elected to include your Pre or Post Production processes, they are on the ends — in red.

Tip: When you click the button to 'Add or Remove Columns', this chart gets automatically re-created.

(Try doing THAT with a home grown template)

Activity Ratio Pie Chart

Activity Ratio = Total Processing Time divided by Total Lead Time

(adjusted for Unit of Measure Conversions and Work Time Available)

This is an often embarrassingly small number that vividly shows how much room there is for improvement.

Tip: You can use the dropdown list to choose whether to chart Activity Ratio or % Value Add, which includes only Value Add activities, and is therefore an even more embarrassingly small ratio.

Work Balancing Chart

The Effective Cycle Time for each process on your Critical Path had better be lower than your Takt Time

or you won't meet your production schedule.

Tip: If a process has Change Over Time and/or Productivity Loss,

then this is a stacked bar chart — showing those components of total Effective Cycle Time.

Process Capacity Chart

The Capacity for each process on your Critical Path had better be higher than Demand or you will have some unsatisfied customers.

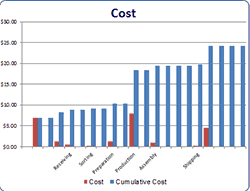

Cost Chart

Shows bars for both: Cost, and Cumulative Cost.

Supply Chain Charts

Special charts and metrics for Quality Screen, Delivery Screen, and Demand Amplification Screen.

Learn more about Supply Chain Mapping

Chart Tips

Hide them

You can hide the Charts section just like you can hide any other unused rows.

Move them

If you don't want to use a chart, just move it out of the Print Area.

Make your own

Notice that there are special features to make it easy for you to create your own charts, using everything you know about familiar Microsoft Excel.

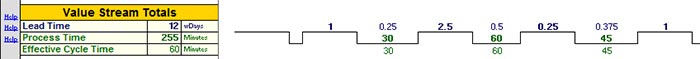

The Time Sum Line

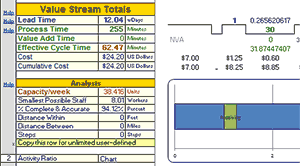

If you have ever before used any value stream map, then your eye should naturally drift down near the bottom of the map, (above the charts), where you will find the Value Stream Totals, also known as the Time Sum Line, or "the castle wall".

If a value stream map has only 3 "bottom line" calculations, they should be these 3:

- Lead Time

- Process Time

- Cycle Time

You will find training for these foundational lean metrics in our Lean Glossary.

And notice that you can also easily hide or unhide additional rows of 'bottom line' metrics for Cost, Steps, and more...

all without programming. You simply unhide the rows that you need.

Andons

Most people don't notice the Andons until they are analyzing their own real-world value stream map

when they notice, "Hmm... why is that number bold red???"

"Wait a second... that process capacity won't meet demand. Or that Cycle time won't meet takt time.

Or we're utilizing our people more hours than we plan to schedule them to work."

"Wow... that was helpful. In fact, those are some of the very most important factors of value stream analysis, and it sure it nice that my Systems2win template makes it difficult to embarrass myself by missing such an important oversight..."

Tip: In the small white cells just to the left of Process Capacity and Utilization, you can enter your own user-defined thresholds for how close to the edge you want to get before your value stream mapping andons turn bold red to alert you to problems.

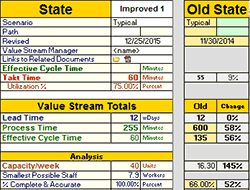

Side-by-Side Comparisons

Import Old State Comparison Data

When you scroll to the right, there's one more button that you can click to Import Old State Comparison Data for eye-catching side-by-side comparisons to answer the question:

"How much better is our proposed Future State vs. the way we've been doing things?"

Value Stream Analysis

The Layers

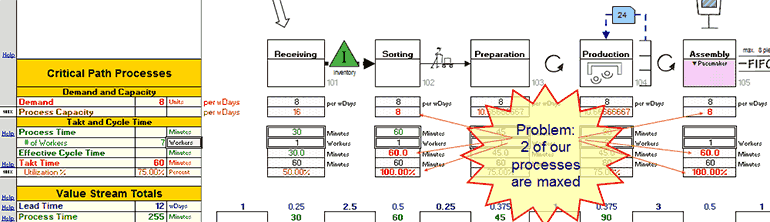

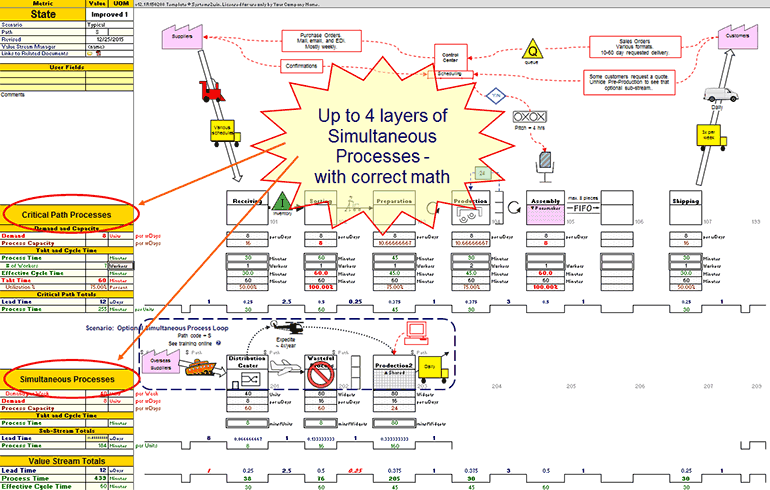

Simultaneous Processes

When you click the button to 'Hide or Show Rows', you will notice that you can have up to 4 tiers (or layers) of Simultaneous Processes.

In other words...

if you have multiple streams of activities that happen at the same time and then later merge together to feed a downstream operation...

then you will REALLY appreciate the advanced features of your Systems2win value stream mapping template to correctly handle the advanced math required to properly analyze simultaneous processes.

Video: Hide or Show Rows

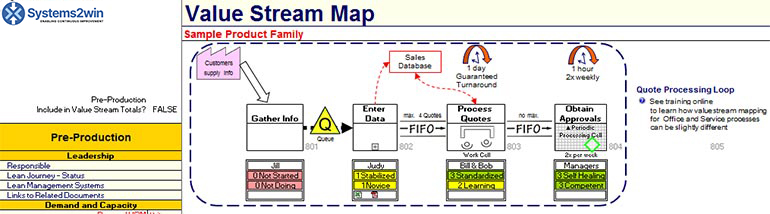

Value Stream Map

Critical Path Processes

If your value stream has multiple streams of simultaneous processes, then you will soon come to appreciate the Systems2win innovation to

always keep all critical path processes in the Critical Path tier

The benefits of this convention are enormous

- Your critical path is extremely obvious

- Math is a whole lot easier to follow and validate

- Math mistakes due to a confusing critical path flow are greatly reduced

- Math for dead ends in Simultaneous Processes are handled correctly

Lead Time already only considers Critical Path.

Process Time, VA, and Steps should always consider dead ends.

Cycle Time for dead end processes can be easily excluded by simply overriding.

The compromise of this convention

In some rare circumstances, the longest cycle time or lead time might be first in one sub-stream and then another.

The proper way to handle this is to always display the critical path process in the Critical Path tier, even if that means that you need to show the physical flow using:

- arrows between layers

- sub-captions just below the Process Boxes - to indicate physical location where the process is performed

Tip: Andons will turn italic red in the bottom Time Sum Line if Lead Time for any Simultaneous Process has larger values than the Critical Path process.

Simply fix the mistake,

by ensuring that the Critical Path tier

contains all critical path processes.

Pre and Post-Production Processes

See our online training for several optional ways to handle segments of your value stream map.

One powerful option is use your 'Hide/Show Rows' button to unhide the optional tiers of processes for Pre and Post Production.

Drill-downs and Roll-ups

The final 'layer' of a value stream map exists 'off the map'.

One of the most powerful features of your Systems2win templates is the ability to easily link to (and roll up data from) related documents.

For example, you might drill down to and roll up data from a Swim Lane Functional Flowchart that has far more detail than would be appropriate for a value stream map.

Value Stream

Leadership

On your Sample sheet, if you click the 'Hide/Show Rows' button to Show All Rows,

you will see the following sample data.

You can optionally hide the Leadership section,but if your goal is to Measure, Analyze, Improve, and Control your value stream (not just draw it) then you will probably find this section very useful.

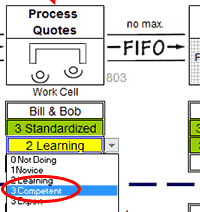

Use the dropdown lists for each process to select your answers to the questions:

"How far along is this team on their Lean Journey?"

"How far along is this leadership team with using effective Lean Management Systems?"

Like every Systems2win dropdown list on any Systems2win template...

you can easily personalize your own dropdown lists

(in ways that your personalizations will be automatically found and transferred every time you upgrade)

The conditional formatting will turn the correct color even if your change the words for your own user-defined codes as long as your dropdown choices start with:

0 for Red

1 or 2 for Yellow

3 for Green

Value Stream Analysis

Demand and Capacity

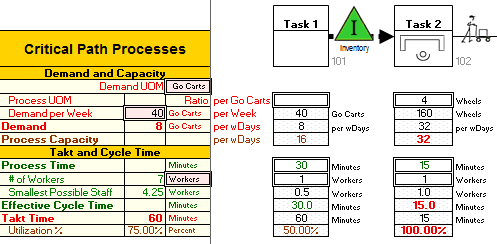

Different units of measure for different processes

It's impossible to have a conversation about Demand and Capacity without first answering the question:

"for what?"

Demand for what? Capacity for what?

What is it that you are delivering to your customer?

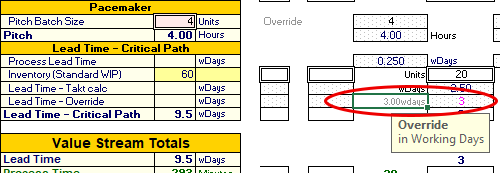

In the pink double-border cells, (see image), you specify:

- Demand Unit of Measure

This is the unit of measure for "the thing being transformed"

which might be medical patients, loan requests...

In this example, we are making "Go Carts"

- Demand per Week

Even if your forecasts use some other time period, you enter Demand per Week but then notice that if you use your button to 'Change Lead Time Unit of Measure', then the next row calculates Demand per your currently-selected Lead Time Unit of Measure, allowing you to switch at any time between working days, calendar days, weeks, or hours

Between the rows for Demand UOM and Demand per Week, notice the row for 'Process Unit of Measure'

If a Process within your value stream uses a different unit of measure, then in the column for that process, you can optionally enter the Ratio, and (in the cell to the right) enter the Unit of Measure.

For example Task 2 is making 4 Wheels per Go Cart.

Notice that all the math for that entire Process is now in "Wheels", rather than "Go Carts"

which is a really good thing, because you can be sure that the person working on that process is not thinking in terms of "How many Go Carts worth of Wheels do I need to make today?"

She is thinking "How many Wheels do I need to make today?"

And now your value stream map is understandable to her.

If every process in your value stream uses the same primary Demand UOM,

(for example, every process in your hospital value stream is transforming the "patient")

then you can simply hide that row

Video: Units of Measure

Andons

In Task 2, notice that some data is bold red — to alert you that there is a problem with your plan.

If Capacity is less than Demand, you have a problem.

If Cycle Time is greater than Takt Time, you have a problem.

If Utilization of your people greater than Work Time Available, you have a problem.

If you see bold red Andons, then you need to Stabilize your process so that it is capable of meeting your customer demand.

Value Stream Capacity

In the Value Stream Totals section

(near the bottom of your value stream map)

you will find calculations with special features that will delight you as you discover them at your own learning pace.

Value Stream Totals for:

- Smallest Possible Staff

- Total Capacity of your entire Value Stream

taking into consideration what if scenarios — like "what if this bottleneck process works overtime?"

- and more Key Performance Indicators that might be important to YOUR value stream

(or perhaps another value stream coming soon to your future)

Value Stream Analysis

Within and Between Processes

Lead Time — When can we have it?

The Lead Time Chart

makes it very easy to see that Lead Time consists of:

the sum of Process Lead Times (time within a process)

+ the sum of Queue Times (time between processes)

and you can optionally choose whether to include or exclude Pre and Post-production processes from your lead time analysis. Learn more

The Lead Time Unit of Measure Converter

allows you to click the 'Change Lead Time UOM' button at any time to switch between:

- Working Days

(excluding weekends and other non-working days) - Calendar Days (to more accurately answer your customer's question: "When can I have it?")

- Weeks

- Hours

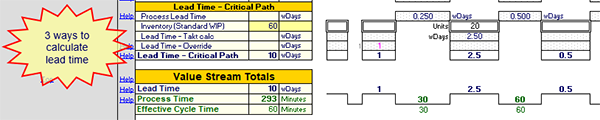

Three ways to calculate lead time

In your Systems2win Value Stream Mapping template v15.1 R180214 or higher, there are 3 ways to calculate lead time.

- You can enter an override value in the Lead Time Override field.

In the cell just to the LEFT of the 'Between Processes' column,

(in other words, it the same column below the primary process...)

enter your override value in 'Working Days'

(and notice how your template automatically converts Working Days into your currently-selected Lead Time Unit of Measure, which might be Calendar Days, Weeks, or Hours, which you can change at any time, by using the Change Lead Time UOM button in the Systems2win menu.

- Lead Time - Takt Calc

In the column just to the RIGHT of the process, enter the amount of Standard WIP Inventory that is usually found both WITHIN that process, and immediately AFTER it

Lead Time Takt Calc = Std WIP * Takt Time

In other words, how long does this stuff usually stay there at the rate that the customer buys it?

- Process Lead Time

If you don't enter data for either Override or Inventory WIP, then Lead Time will equal Process Lead Time.

In other words, how long does it take to make a batch of this stuff, and then immediately pass it to the next operation? (assuming zero queue time between processes)

Process Lead Time

Time WITHIN each process

Unless you override it, Process Lead Time is calculated as

Cycle Time * Pitch Pulse Batch Size

Why would you override Process Lead Time?

If 'the thing' continues to be transformed in a way that does not involve the operator...

(perhaps drying, curing, growing, fermenting...)

then you can override Process Lead Time

Queue Time

Time BETWEEN processes

Queue Time

If you are using an older template that has rows for Queue Time, then the math is a little different.

Your template will calculate Lead Time as the sum of all Queue Times + all Process Lead Times.

It will always include Process Lead Time as a a separate value from Queue time, so you need to enter the amount of Queue Time BETWEEN processes.

Get a free upgrade

If your Annual Maintenance is current, and you like the new way better...

(to enter 1 combined value for the Lead Time, considering both the Process Lead Time and the time that it waits AFTER each process...)

then you can request us to send you the latest new templates at any time.

Distance

Distance Within a process is usually measured in feet or meters.

Distance Between a process is usually measured in miles or kilometers.

All default units of measure are defined in the pink cells in the headers for the Critical Path.

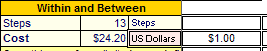

Steps

A "step" happens anytime that the thing being transformed could be handed off, in either:

1) sub-steps WITHIN each process

2) transportation or delays BETWEEN each process

Perhaps the most common mistake of value stream mapping

is not understanding the definition of a Continuous Flow Process Box

and how there might be dozens of sub-steps that should be depicted in a related flowchart

(and NOT split into separate Process Boxes on the value stream map)

The 'Steps' field on your value stream map gives a much more succinct insight into possible process complexity — and (if important) people can click link icons to drill down to related documents that explode the details of the underlying complexity.

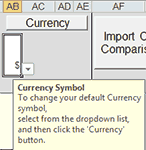

Cost

Currency button

Your Systems2win value stream mapping template has a special button that makes it exceptionally easy to instantly convert every currency cell in your value stream map to a new currency.

Simply use the dropdown list to select your desired currency symbol, and then click the 'Currency' button.

Because many currencies use the same symbol, you can also clarify exactly which currency you are using, by entering your currency description in the pink field in the headers for the Critical Path.

Cost Chart

The pre-formatted Cost Chart depicts both Cost and Accumulated Cost.

(and notice that unlike your home-grown template, this chart still works even if you hide the rows containing the source data — when you want to minimize clutter in the finished value stream map that you publish for distribution)

Value Stream Analysis

Critical Path Deep Dive

One huge benefit of the Systems2win convention of keeping all Critical Path processes in the same tier

is that this makes it far easier for you to use everything you know about familiar Microsoft Excel

to write your own user-defined formulas for ANY Key Performance Indicators that are critical to the success of YOUR value stream

AND... it makes it far easier for you to use your pocket calculator to validate and trust the (extensive) calculations that we have already programmed for you.

Critical Path Analysis calculations that you might never be able to program for yourself, such as...

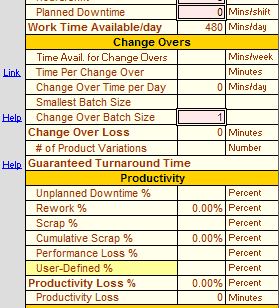

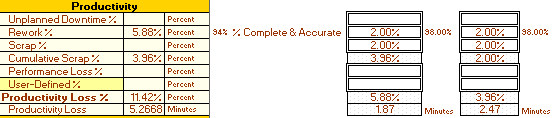

Productivity

Productivity Loss % = the compounded losses of Downtime, Rework, Cumulative Scrap, Performance Loss, and User-Defined %

Productivity Loss is identical to Overall Equipment Effectiveness OEE Loss. We simply renamed it for office, service & medical industries that can't relate to "equipment" as a factor affecting productivity.

There are are large number of extremely useful calculations happening beneath the curtain.

To validate and trust the numbers, we suggest to start by entering some simple round numbers that you can easily cross reference using your pocket calculator.

Once you have studied and validated the calculations enough to trust your new Power Tool, you will soon wonder how you ever considered attempting to do this type of value stream analysis with just a pencil and a pocket calculator.

Download your free trial now, and put it through your paces.

Advanced Tips for Productivity

If you just want to plug an override number for Productivity Loss % simply enter your guesstimate number into the row for 'User-Defined %', and leave all the other Productivity factors blank.

If you override Process Capacity then it calculates Overall Productivity Loss as Good units produced / (Work Time Available / Cycle Time)

Staff unavailability is simply a form of Unplanned Downtime %

Don't just read this with glazed eyes...

Download your free trial, and learn how to use these features to increase YOUR productivity

% Complete and Accurate (Rework)

Percent Complete and Accurate is the flip side of Rework.

In other words, if a process has 3% Rework, it has 97% Complete and Accurate.

Lean Manufacturing tends to prefer to use Rework;

Lean Office and Service tend to prefer % Complete and Accurate.

Your Systems2win template provides both calculations.

Cumulative Scrap

Scrap doesn't just affect one process.

Every upstream process needs to produce enough to keep feeding the downstream process enough to meet ultimate customer demand.

Your Systems2win value stream mapping template calculates the effects of Cumulative Scrap correctly.

Guaranteed Turnaround Time

What is the longest time that your customer will ever wait for any product variation within the product family produced by your value stream?

In other words...

what is the rock-solid answer to your customers' most common question:

"When can I have it?"

Use the special features in your Sytems2win Value Stream Mapping template to calculate Guaranteed Turnaround Time

Optimum Batch Size

If Change Overs are an important consideration affecting the flow of your value stream, then the change over optimization calculations in your Systems2win Value Stream Map can easily justify a very fast Return on your entire Investment.

Path Codes and Scenarios

You should NEVER show multiple scenarios on an "As Is" value stream map, but it is rather common to show multiple scenarios on a single "Future State" map.

See our online training to choose between multiple ways to depict multiple scenarios on a single map with Path Codes and Scenarios as the most powerful and popular option.

Value Stream Analysis

Anything Else

User-Defined Fields and Metrics

Remember, your Systems2win Value Stream Mapping template is an Excel template.

It isn't "like" Excel. It "is" Excel.

It doesn't force you to learn some confusing interface to import and export data to and from Excel.

You can use absolutely everything you know about familiar Microsoft Excel to add unlimited rows of user-defined fields and unlimited user-defined lean metrics and unlimited user-defined charts and (if you're that into it...) even user-defined Visual Basic macros

You're not wasting your time learning yet another new software program...

You are becoming a more and more expert user of the single most popular software in the world of business...

Microsoft Excel

And (of course) your Systems2win value stream mapping template has special features to make it even easier to leverage your Excel skills beyond what you might have thought was possible.

Learn more about user fields

Return to home training page for how to do value stream mapping

When to use this tool

in a Typical Lean Journey for Lean Transformation

- Phase 0)

Firefighting - Phase 1) Prepare Your Leadership

- Phase 2) Design Value Streams to Flow

- Phase 3) Analyze, Stabilize, Visualize, and Standardize each process

- Phase 4) Continuously Improve

Road map for a typical

Lean Transformation

The right tools to

Define, Measure, Analyze, Improve, and Control

your value stream maps

(not just draw them)

Own Yours Now

If your organization has

not yet provided a license,

own yours now

Training and Coaching

Consider Training and Coaching to support your teams to succeed

Training to get you started.

Tools you won't outgrow.

Schedule a Conference

Schedule a conference

to discuss your challenges

with an experienced lean advisor